|

|

|

|

|

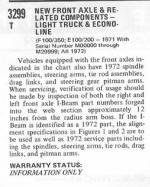

Installing Disc Brakes on Your 2WD Pickup |

|

|

|

PAGE [

1 ] - [ 2

]

If you're like most people, you like being able to come to a rapid and

complete stop when you push down on the brake pedal. When the auto

manufacturers began to discover the advantages of using brake discs on

the front end instead of drums, the option quickly became a favorite for

consumers, so much so that it didn't take long for most manufacturers to

make front disc brakes standard on most of their vehicles. However, if

you're the owner of an older Ford truck, more than likely it's still got

the old tried-and-true four-wheel-drum setup.

Although Ford started installing disc brakes on the F-250 in 1968, they

were not factory-installed on the F-100 until 1973...the first year they

were standard equipment on all F-100 through F-350 trucks. However, the

front disc brake setup on the '73-'79 trucks is a direct bolt-on for

Twin I-beam-equipped trucks back to 1965...if the I-beams and spindles

are swapped as a pair! (You CAN do some mixing/matching as detailed

below, but it's always better to keep I-beams and spindles properly

mated.)

While there ARE disc-brake

conversion kits available, the easiest way to convert your truck to disc

brakes is to simply find a '73-'79 donor truck and salvage all the brake

hardware. If you've got an F-100, you'll need to find an F-100/F-150 to donate

it's parts, as few F-250 disc brake spindles will fit your F-100

I-beams. (In addition, the F-250 calipers are a dual-piston design which

is not as desirable and would give you an 8-lug setup on the front

instead of 5-lug.)

FYI:

The disc brake setup is nominally wider than the drum-brake versions, so your track width

will marginally increase, but not enough to notice or for it to be an

issue unless you're using wider wheels/tires that barely clear the

fender as/is.

However, there IS a

difference in some disc brake setups used on the F250/F350 trucks.

Depending on the axle rating, some F250 disc brake setups use F-100 or

even F-350 parts. And if that's not enough, the larger units also

have 9/16" wheel studs vs. the 1/2" studs of the smaller units.

Therefore, when performing this swap on an F250, be sure to check the

GVW rating on the donor truck to be sure that you know what you're

getting. Use this handy chart I put together after spending an entire

evening researching kingpin diameters:

|

'65-'79 FORD TRUCK TWIN I-BEAM

AXLE MODEL APPLICATION CHART |

|

MODEL |

DESCRIPTION |

KINGPIN

SIZE (IN.) |

| 65-67 F100 |

|

6.35 x .85 |

| 68-70 F100 |

|

| 71 F100 |

I-beam forged C8TA 3008 or 9-B |

| I-beam forged D2TA 3008 or 9-DA |

| 72 F100 |

|

| |

| |

| 65-70 F250 |

w/ 12-1/8" x 2" drum brakes |

6.35 x .85 |

| 66-70 F250 |

w/ 12" x 2-1/2" drum or disc brakes |

| 71 F250 |

I-beams forged C8TA 3008 or 9-B - Before

Ser. M00,001 -

w/12-1/8" x 2" drum brakes |

I-beams forged D2TA 3008 or 9-DA From Ser.

M00,001 -

w/12-1/8" x 2" drum brakes |

I-beams forged C7TA-8-9-A or C8TA-8-9-B -

w/12" x 2-1/2" drum or disc brakes |

I-beams forged D2TA 3008 or 9-DA (From Ser.

M00,001)

w/12" x 2-1/2" drum or disc brakes 6100# - 6900#

GVW |

I-beams forged D2TA 3008 or 9-BB (From Ser.

M00,001)

w/ 7500# GVW |

6.45 x 1.05 |

| 72 F250 |

w/ 6200# GVW axle I-beam stamped D2TA 3008

or 9-DA

(From Ser. M00,001) |

6.35 x .85 |

| w/ 6900# GVW axle I-beam stamped D2TA 3008

or 9-DA |

| w/ 7500# or 8100# GVW axle I-beam D2TA 3008

or9-BB |

6.45 x 1.05 |

| |

| 67-72 F350 |

|

6.45 x 1.05 |

| |

| 73-74 F100 - 2/W/D |

|

6.35 x .85 |

| 75-79 F100/150 - 2/W/D |

|

6.49 x .85 |

| |

| 73-74 F250 (Regular Cab) - 2/W/D |

With 6200 lbs. G.V.W. |

6.35 x .85 |

| With 6900 lbs. G.V.W. and without 460 C.I.D.

engine |

| With 6900 lbs. G.V.W. and 460 C.I.D. engine |

6.45 x 1.05 |

| With 7500 and 8100 lbs. G.V.W.

|

| 75-79 F250 (Regular Cab) - 2/W/D |

With 6200 thru 6900 lb. G.V.W. |

6.49 x .85 |

| With 7500 thru 8100 lb. G.V.W.

|

6.45 x 1.05 |

| 74 F250 (Super Cab) - 2/W/D |

6300, 6900 & 7500 lb. G.V.W. |

| 8100 lb. G.V.W. |

| 75-79 F250 (Super Cab) - 2/W/D |

|

| 73-74 F250 (Crew Cab) - 2/W/D |

|

| 75-79 F250 (Crew Cab) - 2/W/D

|

|

| |

| 73-74 F350 - 2/W/D |

3.8M |

6.45 x 1.05 |

| 75-79 F350 - 2/W/D |

|

One other note: I spent

some time comparing the F-100 I-beams from '67-'79 Ford trucks and have

found a few interesting items. In addition to the differences in

kingpin diameters and heights, there was also a change in the steering bump

stop on the I-beams/spindles for certain years. You can read the entire article

"Comparing I-beams and spindles" for

more information, but basically it comes down to this:

-

If you're using

'75-'79 spindles, use '75-'79 I-beams and kingpins

-

If you're using

'68-'74 spindles, use '68-'74 I-beams and kingpins

-

If you're using '67

I-beams, use '73-'74 I-beams and kingpins. However, the round pin used

for the bump stop in the '67 I-beam may need to be trimmed or modified,

as

needed.

-

1965 has

one-year-only kingpins, so if replacing spindle out and replacing

kingpins, use 1965 kingpins.

NOTE: These recommendations are not based as much on kingpin size as

they are by steering stop (bump stop) configurations between the

different years of I-beams and spindles. You might find that by

mixing/matching certain years of I-beams and spindles, your truck's

turning radius could either be increased (meaning likely tire rub at

full turn) or decreased.

You can now see why

it's highly recommended to simply find yourself a '73-'79 donor truck

and get ALL the brake parts from this truck for use in your project.

It alleviates a LOT of headaches involved when attempting to mix and

match parts.

Well, enough of the babble....let's get started! Follow along as I convert my '67 2WD SWB to disc brakes using all the

parts from a '79 F-150 donor truck.

|

|

FRONT-END REMOVAL

The disc brake spindle is connected to each I-beam with

a kingpin. While it's possible to drive the kingpin out manually while

working on a parts truck in the field or salvage yard, it's going to

require a LOT of effort. However, the ENTIRE front end can be dropped

out as a unit in less than an hour with hand tools, so this is

definitely recommended. You can then take your parts home and fight with

the kingpin in your shop or garage, where you have access to tools and

cool liquid refreshments. Here's what you need to do to drop the front

end:

1) Remove

two bolts holding the coil spring retaining strap at the top.

2) Loosen the upper shock absorber nut about 90%, but don't remove it

completely.

3) Disconnect the tie rod from the steering box's Pitman arm and

separate the drag link from the center link.

4) Disconnect the brake lines at the caliper.

5) Remove the large nuts holding the rear of the radius arms to the

frame brackets.

6) Remove the I-beam pivot bolts and pry the I-beams out of the frame

brackets.

At this point the suspension assembly should be hanging by the shock

absorbers. Put a hydraulic jack under one side's brake assembly and jack

it up a bit to relieve the tension, then lay on your back and give that

side a couple good hard kicks forward to slide the radius arm out of the frame

bracket. Then remove the shock absorber nut and lower to the ground.

Repeat for the other side.

Other pieces

you need to be sure to grab from the donor truck include:

- Brake

hose frame brackets (see Fig. 4)

- Master

cylinder/brake booster

- Brake

proportioning valve - also snip the end off the valve's wiring, to

splice into your existing harness so your brake warning light works

properly. You'll also need the fittings going into the valve, so if

you're planning on replacing all the lines, just snip them at the

valve, leaving yourself several inches of line.

- Front

steel brake lines (these probably need replacing, but grab 'em anyway

to use as templates for bending your own lines)

-

steering linkage (and possibly the Saginaw steering box's Pitman arm - more on this

below)

Most of the brake components will be replaced with new parts, including

the rotors, calipers, bearings, hoses and pads. |

Fig. 1 - A quick before shot. The truck is setting on jackstands,

but the front end loader is also supporting the truck, just as a backup.

Fig. 2 - It only took me about 30

minutes to drop the front end from this '70 F-150.

Fig. 3 - Here's the front end unit

ready for it's new home.

Fig. 4 - I found that one of the brake line brackets was riveted to

the frame, while the other was simply bolted. Since I didn't feel like

messing with removing the factory rivet, I just grabbed another bolt-on

bracket from a different truck. |

|

|

|

IMPORTANT NOTE:

Ford did some redesign of the front end components beginning on

late-'71 trucks, including the Pitman arm. If you're installing the

disc brake setup on an early-'71 truck or earlier and attempt to use

your original steering linkage, you'll might discover that the tie

rod end will not fit the Pitman arm. You'll either have to use the

steering box (or at least the Pitman arm) from the donor truck. Read

the scans at right from the factory Technical Service Bulletins for

more info. |

Fig. 5 |

Fig.

6 |

|

For more detailed

information on the differences in steering hardware mentioned in the

above TSBs, visit the

Steering/Suspension Component Variations

page. (This page is currently under construction, but there are some

comparison photos which will help show the variations.) |

|

|

|

ABOUT KINGPINS &

BUSHINGS

Once you get your parts home, you can start the disassembly. Remove the

calipers, rotors, springs, radius arms and steering linkage. You should

be left with the I-beams and spindles, held together with the kingpins.

While it's possible to remove the kingpins in your shop,

I'd highly suggest just dropping them off at your local machine shop and

having them press them out with a hydraulic press...a 15-20 minute job

for them that shouldn't cost you more than about $20-$30. If you're not

planning on cleaning up and painting your I-beams prior to

reinstallation, be sure to bring your new kingpin set for them to press

in at the same time. The kingpin kit should only run you about $50 and

it's installation will be another $50-$75...well worth it.

|

Fig. 7 - Here are the kingpin

bushings that were removed from my '79 spindles. You can still see

the Ford logo. Also note the 'jigsaw puzzle' style of connector of

the rolled bushing. |

Kingpin bushings are

available in bronze and nylon versions. The bronze bushings are

actually steel with a bronze inner lining and will need to be reamed

(NOT honed!) by the machine shop after installation to properly fit the

kingpin. The nylon bushings don't require reaming and can simply be

installed by hand. However, while the bronze bushings will give you

100,000 miles or more of service, the nylon versions don't last nearly

as long. Some users report having to replace these after 30,000-40,000

miles. And while they're easier to replace when they DO wear out, who

wants to go through this again?? Just use the bronze bushings, keep 'em

greased up and you'll probably never have to worry about them again.

The bronze bushings are

'rolled' bushings...that is, they are manufactured from flat stock and

then rolled around into a tube and secured with a connection which bears

a resemblance to a jigsaw puzzle connector (See Fig. 7). Out of the box,

they are not 'true', which is why it's mandatory to ream them to snugly

fit the kingpin.

Well, let's get those kingpins out!.....

PAGE [

1 ] - [

2 ] |

|

|

Want to link to

this site? Please save this banner to your hard drive to place on your

webpage.

The correct link to use is

http://www.fordification.com

|